This article is focusing on the introduction of Exhaust Gas Recirculation (EGR) systems. For more details about components and types (architectures) of EGR systems, read also the following articles:

The combustion process of the air-fuel mixture within an internal combustion engine is incomplete. Therefore, the exhaust gas contains pollutant emissions such as: carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC) and particulate matter (PM). All pollutant emissions from internal combustion engines have harmful effect on human life and environment.

Nitrogen oxides form at high temperature and when there is oxygen in excess. Both these conditions are present during the combustion process of a diesel engine, in most of the operating points. Since diesel engines are not throttled, there is always air/oxygen in excess and, especially at high loads, high combustion temperatures. For these reasons a diesel engine has more nitrogen oxides in the exhaust gas compared with a gasoline engine.

Image: Pollutant emission levels function of air-fuel ratio – petrol (gasoline)

Credit: [2]

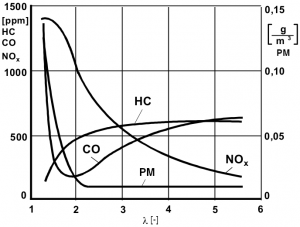

Image: Pollutant emission levels function of air-fuel ratio – diesel

Credit: [2]

In a gasoline (petrol) engine, exhaust gas pollutant emissions are highly dependant on the air-fuel ratio. Rich mixtures (lack of air, λ = 0.9) cause more carbon monoxide (CO) and hydrocarbons (HC). Lean mixtures (excess air, λ = 1.1) cause more nitrogen oxides (NOx). In diesel engines, which always run on lean mixtures (λ = 1.5), the amount of nitrogen oxides in the exhaust gases is high.

Exhaust Gas Recirculation (EGR) is a system that allows the exhaust gases to be recirculated back into the intake manifold. This process leads to a significant reduction in nitrogen oxides (NOx) emissions because it reduces the two elements underlying its production: oxygen in excess and combustion temperature.

There are two types of EGR:

iEGR works by retain hot residuals from the previous engine cycle [3]. The residual gas fraction can be defined as the burnt gas mass divided by the total in-cylinder mass (burnt and unburnt) before to the start of combustion (i.e. at intake valve closing). The amount of exhaust gas trapped inside the cylinder depends on factors such as the valve timing, engine speed, and pressure differentials. Means of adjusting the residual gas fraction generally rely on mechanisms such as two-stage cam-lift, camshaft phasing, variable valve actuation, and fully variable valve actuation.

EGR (external) is the main technology used by vehicle manufacturers for the reduction of NOx emissions on diesel engines. It is more efficient than iEGR mainly because the exhaust gases can be cooled before reentering the cylinders, the amount of exhaust gases recirculated is higher and the flow is better controlled.

Image: NOx level and combustion maximum temperature function of EGR rate

Credit: [1]

The emissions reduction is achieved from the fact that the exhaust gases, mainly carbon dioxide (CO2), nitrogen (N2), water (H2O) and oxygen (O2), acts as a diluent, which in combination with the high specific heats associated with the triatomic molecules, results in the direct reduction of the adiabatic flame temperature and the formation kinetics of nitrogen oxides (NOx). Since the specific heat capacity of both CO2 and water vapour is greater than that of oxygen, the gas temperatures within the engine cylinder during combustion is reduced.

By recirculating the exhaust gas into the intake, some of the oxygen required for the combustion is replaced by inert (exhaust) gases, which leads to the reduction of excess oxygen. Also, because the exhaust gases absorb some of the heat generated during combustion, the maximum combustion temperature per engine cycle is also reduced.

The EGR system significantly reduces the amount of NOx, but if too much exhaust gases are introduced into the intake, it can have an impact on the increase in emissions of carbon monoxide (CO), hydrocarbons (HC) and particulate matter (PM), as a result of incomplete combustion due to lack of air (oxygen). The EGR system is active mainly during partial engine loads and at low and medium engine speed areas, where oxygen is in excess. In the high engine load (torque), the EGR system is deactivated, the cylinders being filled only with air, ready for combustion.

Depending on the pressure of the recirculated exhaust gases, there are two types of external EGR systems:

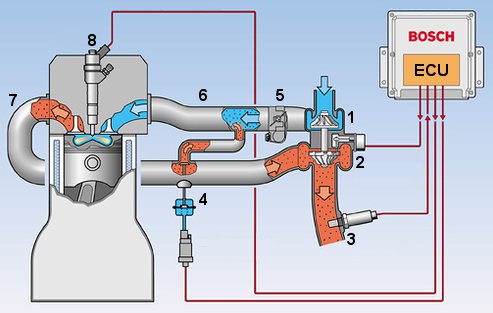

Image: High pressure (external) EGR system

Credit: Bosch

The exhaust gas recirculation in the intake manifold is not continuous during engine operation. The electronic control unit (ECU) controls the EGR valve (4) to allow the exhaust gas to enter the intake manifold. On turbocharged engines, the control of the exhaust gas flow is also done by means of the throttle (5) which, when closed, lowers the pressure in the intake manifold and facilitates the flow of gases from the exhaust manifold.

Image: NOx emissions limits for Euro pollutant emission standards

EGR control should be done in such a way as to find the optimal compromise between pollutant emissions and the engine’s torque output. Starting with Euro 3 pollutant emission regulation, the EGR has become standard equipment for most diesel-powered vehicles. The EGR has proven to be an efficient and inexpensive system to reduce nitrogen oxide emissions.

The lower the temperature of the exhaust gases, the higher the density. By cooling the exhaust gas, before recirculation into the intake manifold, the efficiency of the EGR system is improved. The more dense inert (exhaust) gases in the intake lowers the combustion temperature by absorbing part of the heat and displaces part of the oxygen in the cylinder. Starting with Euro 4, the EGR diesel engines are fitted with an exhaust gas cooler and a bypass valve.

Image: High pressure EGR system with cooler

Credit: Hitachi

In order to have an exhaust gas flow into the intake manifold, the exhaust gas pressure must be higher than the intake air pressure. On a turbocharged diesel engine this can be achieved either by using the geometry of the turbine vanes (VGT) or by fitting a throttle on the intake manifold. By closing the VGT vanes, the exhaust pressure builds up, higher than the intake pressure, which allows the exhaust gas to flow into the intake. By using a throttle in the intake manifold, the pressure after the throttle drops, below the exhaust gas pressure, which also triggers the exhaust gases to flow into the intake manifold.

The EGR rate is defined as the percentage of exhaust gases from the total gas mass induced into the engine. For example, an EGR rate of 33 % means that a third of the gas which enters the cylinders is actually exhaust gas and 67 % is fresh air.

The higher the EGR rate the lower the NOx emissions levels. Nevertheless, too much exhaust gas into the cylinders can have a negative impact on the engine performance in terms combustion stability, which can degrade the torque output and increase hydrocarbons (HC) and particulate matter (PM) emissions.

Turbocharged diesel engines equipped with fixed geometry turbochargers can recirculate up to 45-50 % of exhaust gas back into the cylinders without major effect on fuel consumption and other pollutant emissions. Gasoline engines, depending on their operating condition, are able to recirculate up to 20 % of the exhaust gases without affecting combustion stability [4].

rate on pollutant emissions and fuel consumption" width="283" height="500" />

rate on pollutant emissions and fuel consumption" width="283" height="500" />

Image: Impact of EGR rate on pollutant emissions and fuel consumption

Credit: Bosch

There are several studies regarding the impact of the EGR system on engine wear and oil degradation. In the study [5], the investigation of EGR and wear was conducted on a test engine operating at 2400 rpm with a particular oil specification and combustion system. The baseline engine was specified at Euro II emission levels and was not rematched when EGR was applied. The main conclusions of the investigation is the EGR can have an impact on the engine wear, which is highly dependant on the level of soot in the exhaust gas.

The majority of the increase of soot in the lubricating oil comes from particulate matter (PM) which adheres to the oil film on the cylinder wall and is scraped down into the crankcase by the piston rings [6]. Regarding engine wear, there are two types of wear: corrosive wear and abrasive wear. Sulphuric acid formed in the exhaust gas and soot cause a breakdown of the oil film and thereby promote the corrosion of the cast iron around top dead centre (TDC) and bottom dead centre (BDC). Corrosive wear is caused by the particle matter (PM) trapped in the oil.

EGR has a different purpose on gasoline (petrol) engines. It is used mainly to reduce the temperature of the exhaust gases, in order to protect the turbocharger and the catalytic converter. Using EGR for component thermal protection is an alternative to rich air-fuel mixture, especially at high load, which results in a significant reduction of the fuel consumption. Also, when the engine is operating at partial loads, by using EGR, the pumping losses are reduced and fuel efficiency improved.

On turbocharged, direct injection gasoline engines, EGR is used to suppress engine knocking. The general principle of spark-ignited wide open throttle exhaust gas recirculation (WOT-EGR) operation is to return cooled exhaust gases to the cylinder at moderate to high loads, reducing unburned gas temperatures to such a level where knock can be adequately suppressed and/or the temperature of the outgoing exhaust gases is sufficiently low so as to preserve the exhaust components [7].

Exhaust gas recirculation (EGR) was first introduced on vehicles in 1970. Now it is used on all diesel powered vehicle as a main system to reduce the level or nitrogen oxides (NOx).

References:

[1] Advanced direct injection combustion engine technologies and development, Volume 2: Diesel engines, Edited by Hua Zhao, CRC Press, 2010

[2] Verbrennungsmotoren, Institut für Maschinenmesstechnik und Kolbenmaschinen (IMKO)

[3] Potential of internal EGR and throttled operation for low load extension of ethanol–diesel dual-fuel reactivity controlled compression ignition combustion on a heavy-duty engine, Vinícius B. Pedrozo, Ian May, Thompson D.M. Lanzanova, Hua Zhao, Centre for Advanced Powertrain and Fuels Research (CAPF), Brunel University London.

[4] Reduction of Steady State NOx Levels from an Automotive Diesel Engine Using Optimised VGT/EGR Schedules, J.G. Hawley, F.J. Wallace and A. Cox, R.W. Horrocks and G.L. Bird, SAE paper, 1999-01-0835

[5] The Effect of EGR on Diesel Engine Wear, A. J. Dennis, C. P. Garner and D. H. C. Taylor, SAE paper, 1999-01-0839

[6] EGR’s Effect on Oil Degradation and Intake System Performance, Jeffrey A. Leet, Terry Friesen, SAE papaer, 980179

[7] Advanced direct injection combustion engine technologies and development, Volume 1: Gasoline and gas engines, Edited by Hua Zhao, CRC Press, 2010